As I mentioned in the introduction, I was taught many different methods of section design, one for each material type, and then other versions at serviceability and at ultimate, and other variations with axial forces thrown in. But there is only actually one method.

Surprised?The only difference between the various situations is the behaviour of the particular combination of materials.

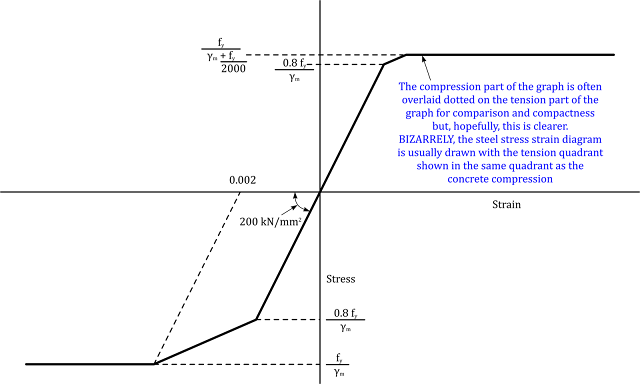

Stress-strain diagrams

The behaviour of any particular material is best understood by looking at a plot of stress against strain. Different codes often use different stress strain curves, but in each case they are just the code author’s particular way of simplifying actual test results.

Figure 4 - BS5400 stress strain diagram for reinforcement (modified as described)

|

|

|

|

Figure 6 - idealised stress strain curve for structural steel (tension side only shown)

|

On the linear elastic section:

stress = strain x Young’s modulus, which is a rearrangement of the definition of Young’s modulus.

On the plastic part of the graph, the strain in the material keeps on increasing without a corresponding increase in stress, i.e. it stretches and stretches, without any extra force required.

This is obviously a simplification of the more realistic graph, shown with the thin grey line, but it is the normal assumption for working with structural steel.

Subtleties: a more realistic stress stain curve would not just be a pair of lines with a sharp break. When the steel starts to yield, the corner of the graph is not sharp, but a gradual curve, as shown in grey. So how do we determine the yield stress ? Think back to the description, above, of elastic behaviour. If we consider the stress strain curve to be straight, followed by a short curve, and followed then by another straight section, then, in the elastic range, loading and unloading a sample will go up the straight line and then back down the same way. But one we get onto the curved section, unloading a sample will immediately start back down a different line, parallel to the linear section. This is where the sample has started to go plastic and when the sample is unloaded, there will be a small permanent strain. Yield is normally taken at a particular “Proof Stress”. As an example, if the critical value is the 0.2% proof stress, then the value will be the stress (partially around the curved bit) where fully unloading the sample will return to a permanent strain of 0.002.

Likewise, the flat plastic section of the graph will probably have some strain hardening, which is a posh phrase for the fact that the stress will actually increase a bit with increasing strain, although the rate will be orders of magnitude less than for the linear elastic part of the curve.

Using stress diagrams in section analysis

I am afraid that the next bit will require a small amount of visual gymnastics. It is something that some people see straight away but it is so simple lot of people cannot get their heads around it: but it is just a way that I use to visualise how things work. The method is shown in Figure 7 via three examples with progressively higher peak strains.

In case you can see through the principle straight away, or just as an introduction, the following demonstrates that the relevant part of the stress-strain diagram, from zero to the maximum strain, can be transposed on to the stress diagram.

|

Figure 7 - steel in compression

|

During any section analysis, and here we are just looking at the compression side to prove a point, the strain will vary linearly from zero at the neutral axis (by definition) to a particular value of strain (to be determined in a later part of the calculation) at the tip of the section. The compression strain diagrams for the three examples are shown as (1). Variations on the stress strain diagram for the material are drawn to the same scale in (2), directly above (1). Since the strain scales are the same, the stresses at the tip of section will be the stresses corresponding to the points directly above the extreme values of the strain diagram. If we “Wipe out” the rest of the stress strain diagram (shown light and dotted to give a visual reference) then we can see how much of the stress strain diagram is relevant for the particular maximum values of strain: these sections have been coloured in a tasteful shade of pink. It should not be too hard to see that the pattern of stress that is highlighted should be mirrored, rotated (look at the order of the letters in the corners of each shape: the x and y axes have merely been swapped to suit the way that we normally look at sections) and “Stretched” to fit the plot of stress versus height. In the examples above, the pink parts of the stress strain curve have just been repeated on the stress diagram at exactly the same scale: the first example is purely elastic, the second is elastic plastic and the third is mainly plastic: I will explain later why the plastic section is actually almost completely plastic but I need to keep some teasers.

This principle of superimposing the relevant part of the stress strain curve onto the stress diagram is the basis of all of the various methods of section analysis and means that the same principle can be used for all forms of section analysis.

Balancing the forces

I have introduced the complicated bit (not) and there is only one very simple bit left. Phrase it however you want – resolved forces must total zero – what goes in comes out – there ain’t no such thing as a free lunch – but the idea is that the total of all the internal forces must equal the externally applied force. In real money that means that in a reinforced concrete section in pure bending, i.e. with no axial force, the sum of the compressive force in the concrete (positive) and the tension force in the steel (negative) equals the applied force (zero). If there is an applied force as well, e.g. in a column, then the sum of the compressive and tension forces equals the applied axial force.

Ten years later ....

I originally wrote this blog in 2012, but after a decade of honing my teaching methods, I have summarised the above into three simple rules. I tell my grads that I can tell them all they need to analyse any section shape, for any material type, to any code, and under bending, axial, or axial plus bending in 22 seconds, but that is only if I am speaking slowly.

To summarise the above:

Rule 1: the strain diagram is a straight line,

Rule 2: use the relevant part of the relevant stress strain curves, and

Rule 3: everything must balance.

That's all folks. This is two terms of a University course (£6k at 2022 prices) delivered in 22 seconds.

The first rule is a simple outcome from the plane section remains plane assumption.

The second simply says to concentrate on the linear parts of the stress strain curve if you are working in a linear analysis (and can then use Young's Modulus) but the entire curve if going beyond this. Obviously, if analysing steel then use steel curve and if analysing chewing gum, us a stress-strain curve for chewing gum.

The third rule is just common sense to say that the total internal force must equal the total applied axial force (taken down the centroid purely because that is how we model things) and the total internal moment must equal the applied moment. If there is no axial force then the total of compressive force PLUS tensile force (which will have opposite signs) will equal zero.

Reinforced concrete at serviceability under pure bending

This is not the easiest of the strength analyses, but it does demonstrate almost everything discussed above in a clear cut form.

When working at serviceability, the stress in the concrete is relatively low and it will remain in the straight line (linear) part of the stress/strain curve. Because the behaviour is linear, the stress is simply equal to strain x Young’s modulus.

The diagram of strain against depth, as always, is a straight line, hence it can be defined by any two points. The easiest point to assume is a particular value for the compressive strain at the “Top” of the section. I use the word “Top” because that is the case for the most common case of a simply supported beam, but the orientation is irrelevant and we could just as easily be talking about bottom for a beam that is hogging, or side for a beam that is being bent sideways.

Fundamental: this is a classic case of the difficulty with some explanations, demonstrated by the continuous bridge aside discussed earlier. It is very hard to describe something without putting in an orientation, but it is vital to be able to keep everything general in your mind, as far as possible. Remember that the value of shares can go up or down but gravity always sucks.

The second point we need to assume is the depth in the section where the stress is zero, i.e. the depth from the top to the neutral axis (which is not the same as the centroid if you remember).

The fundamental assumption with the behaviour of concrete is that it cannot take any stress in tension. This is, in fact, a slight exaggeration since concrete can take a small tensile stress before it cracks, but since concrete can crack without any externally applied strain, e.g. through shrinkage cracking, then no tension stress can be relied on so it is ignored: and purely by coincidence, it makes the arithmetic easier too so it is a win win assumption.

Aside: one of my favourite instructions for my grads is to be lazy in everything we do – this is nothing to do with being slapdash, but is more about being efficient. The above is a nice example of simple being efficient at the same time as being rigorous – yeah us !

Figure 8 - reinforced concrete analysis at SLS - no axial force

The stress diagram for the concrete forms a triangle “Above” the neutral axis. The tension reinforcement is (hopefully) on the tension side of the neutral axis. Once we have assumed a peak concrete strain and a depth to the neutral axis, the strain in the steel can be calculated using similar triangles and hence the steel stress can be calculated. The force in the concrete, and the force in the steel can now be calculated, and the two assumed values varied until the total force is zero. It works out that, for a rectangular section, the depth of the neutral axis only depends on a series of knowns, i.e. the depth to the reinforcement, the proportion of steel and the ratio between the Young’s moduli of steel and concrete. The peak strain in the concrete, and hence the stress, as well as the stress in the steel, follow on from the depth of the neutral axis and then depends on the applied moment.

The simplest hand calc for this case is called the modular ratio method. The way I was taught used a chart from Reynold's Reinforced Concrete Designer Handbook. This involved working out any one of a number of values, drawing a line across a chart, and reading off the remaining values. The way it was used depended on whether we knew the amount of steel and wanted to calculate the stresses, or whether we knew the moment and wanted to design the steel.

But it all boiled down to one equation

where x is the depth to the neutral axis

d is the depth to the centroid of the reinforcement (please note that d is measured to the steel centroid and that the total depth, when used, is usually referred to as h. One common usage of h is in BS 8110 charts for columns under combined bending and compression)

m is the modular ratio Esteel / Econc

ρ is the proportion of steel i.e. Asteel / (b.d)b is the width of the concrete.

Fundamental: this equation refers to a rectangular section of concrete. Since the concrete below the neutral axis is assumed to be ineffective, it could be used for, say, a tee section provided that the neutral axis was in the flange. This is a typical case of being careful to understand where any equation comes from to make sure that it is actually valid for your particular case.

This can easily be fitted into a spreadsheet as the basis for any calculation. Since the concrete stress block is triangular, its centroid is 1/3rd of the depth from the top, so the lever arm

Having told you to question everything (and if I haven’t done so then I am doing so now) you should now be asking me to prove this. What is that I hear ? Ok then …

Aside: please note that I am cheating outrageously in the proof below, because the force in the concrete does not equal the force in the steel, they must actually be of equal magnitude but opposite sign so that the total is zero. The peak strains should be of opposite signs as should the lever arms. But in this proof everything drops out and you can either conclude that a) I know what I am doing, b) I am very lazy, c) I did not want to confuse you too much, or d) all of these. I will try to do better in future because sign conventions are very important.

Let strain at top of concrete = εconc and strain in reinforcement = εsteel .

By similar triangles:

The force in concrete has a triangular pattern so the average is half the peak:

Force in steel:

The area, down to the tension steel (which is all we are interested in for a pure bending case) equals b.d, and dividing As by b.d we get the proportion of steel ρ. Also, Esteel divided by Econc is the modular ratio m so:

Almost there.

If we now multiply each term by (x/d) then we get a quadratic equation in (x/d):

Those of you who are racing ahead will recall the solution of:

So:

Cancelling out the 2’s, including the 4’s in the square root we get:

Which then rearranges to:

Round of applause please.

The nice thing is that you only have to check my proof and then remember that the equation exists … and that the method boils down to a straight line strain graph, application of the relevant stress strain curves and a balancing of the forces.

From the calculation of x/d, you can carry this on to work out the forces in the concrete or steel, using the lever arm z defined earlier, and check your material stresses against the relevant code limits. If you need to do a crack width calculation, you can extend the strain calcs down to the level that you are interested in and go on from there. Etcetera etcetera etcetera.

The formulae above only work for a rectangular section. But if you have a complex shape, like a voided deck, exactly the same rules are used, you just have to use a tool like a spreadsheet to work out the stresses, and hence forces, over a series of (say) horizontal strips based on assumed strains, and then vary those strains until the forces balance and the moment from the internal stresses equal the externally applied moment.

Simples !

Simples !

Reinforced concrete at serviceability with bending moment and axial force

The principal is exactly the same if an axial force is applied as well. The only difference is that there is no easy formula and you either need to numerically find the answer by varying the two controlling strain values (at the two extremes of the section) until the force and moment balance out.

Fundamental: this is where the difference between the neutral axis and the centroid is very important. The neutral axis can move up and down depending on the amount of rebar and the combination of moment and axial force. But any calculations that you have done to determine the axial force will have assumed that it runs down the centroid, and should therefore be applied there during any section capacity calculation. It is therefore easier to calculate moments about the centroid with the axial force not coming directly into the answer.

Hint: you can use any tools that you want, but I usually find the spin button very useful. This is a control that can increase or decrease the integer value in a control cell between specified values. The value limits can be set to anything between 0 and 30,000, but those are the outer limits. If I wanted to set a value for the depth to the neutral axis accurately then I would choose a maximum of 2/3rds of the depth (even halfway down is probably too deep since it means that there is too much reinforcement: ultimate failure of an over reinforced section is sudden and catastrophic – bad – as opposed to a lightly reinforced beam which forms large cracks and fails with warning). I would then do the calculation using a depth that was x/30,000 of that 3/5ths of the section depth and vary the controlling value using the spin box. The example does this with the depth set to x/50,000. You can set as many controls as you want, e.g. for the depth to NA and for the concrete strain, and if I have a lot of variations to do I often create three spin boxes to control the same cell and use them for coarse, medium and fine adjustments since each button can be set to change the control cell by a different integer number.

Hint: you can use any tools that you want, but I usually find the spin button very useful. This is a control that can increase or decrease the integer value in a control cell between specified values. The value limits can be set to anything between 0 and 30,000, but those are the outer limits. If I wanted to set a value for the depth to the neutral axis accurately then I would choose a maximum of 2/3rds of the depth (even halfway down is probably too deep since it means that there is too much reinforcement: ultimate failure of an over reinforced section is sudden and catastrophic – bad – as opposed to a lightly reinforced beam which forms large cracks and fails with warning). I would then do the calculation using a depth that was x/30,000 of that 3/5ths of the section depth and vary the controlling value using the spin box. The example does this with the depth set to x/50,000. You can set as many controls as you want, e.g. for the depth to NA and for the concrete strain, and if I have a lot of variations to do I often create three spin boxes to control the same cell and use them for coarse, medium and fine adjustments since each button can be set to change the control cell by a different integer number.

If you have never come across the spin control, add the developer toolbar in file, option, customise ribbon and then click on the developer tools to add it to the toolbar.

Reinforced concrete at ultimate under pure bending

This one is either very easy, or a bit detailed, depending on how rigorous you want/need to be. The normal behaviour for reinforced concrete has the concrete failing first, although it is good practice for the rebar to reach yield first (and some codes reduce the calculated capacity by a percentage if the rebar does not yield).

Figure 9 - reinforced concrete analysis at ULS - no axial force

A typical code approach specifies a particular crushing yield strain at the extreme compression fibre. The stress diagram follows the full range from zero at the neutral axis to compressive yield at the extreme fibre. As can be seen in the concrete stress strain diagram in Figure 5, there is usually a short parabolic part ending in a larger rectangular part at full yield.

In BS5400, the maximum stress equals 0.45 fcu and can be applied rigorously, by equation or by slices in a spreadsheet, or a reduced value of 0.40 fcu can be applied over the full depth. For a rectangular section there is a simple formula using the uniform stress pattern: it gives a very similar result for a rectangular section to the rigorous method. There is also a second check which does not allow the neutral axis to be taken below halfway. However, on a bridge with a voided deck, like a box girder, it is usually better to take the higher 0.45 fcu over the top flange, since the loss in stress over the parabolic section is limited to the webs, which are much narrower. BS5400 also has rules which require an additional 15% capacity, i.e. you divide by 1.15, if the steel has not reached the plateau of the stress strain diagram.

In the American bridge code AASHTO, the full peak value is applied over a rectangle, but the rectangle is assumed to stop at a particular proportion of the depth to the neutral axis which depends on the strength of the concrete. For lower concrete strengths, this is 85%of the depth so effectively they are taking a uniform stress equal to the peak, but with nothing over the first 15% from the neutral axis. You can still apply the stress routine rigorously and, again, this is more important for voided sections.

In the Eurocode, you seem to be able to do whatever you want, with either a parabola/rectangular profile, triangular/rectangular or a rectangle over most of the depth (similar to AASHTO).

This is another one of the nasty ones where you have to do it the hard way, by finding the strains at the relevant locations. Again, the force is applied along the centroid, so that is the best place to take moments about. Otherwise it just follows the general methods for ULS reinforced concrete.

Fundamental: please be very careful with concrete specification. BS5400 uses cube crushing tests. Other codes use cylinder tests, but you need to check very carefully whether that cylinder test is a crushing test applied along the centreline to the ends or a splitting test with the force applied across the diameter. I am saying nothing except “Make sure that you use the correct results in the correct codes”.

Reinforced concrete at ultimate with bending moment and axial force

This is another one of the nasty ones where you have to do it the hard way, by finding the strains at the relevant locations. Again, the force is applied along the centroid, so that is the best place to take moments about. Otherwise it just follows the general methods for ULS reinforced concrete.

Structural steel at serviceability under pure bending

At serviceability, most codes will limit the steel to some relatively high proportion of the yield stress, but not actually as far as yield. We are therefore working on the straight section of the stress strain curve from the compression side to the tension side.

Elastic analysis of steel sections is probably the easiest of all the section analysis techniques that you have been taught. You work out the Second Moment of Area, aka I, divide this into the applied moment, and then calculate the stress at any level by multiplying by the distance from the centroid.

Easy isn’t it?

But have you ever wondered why the centroid and why the Second Moment of Area?

Aside: this is where the camera in your computer has just been automatically turned on so that I can take a picture of the puzzled look on your face as you try to remember if you ever knew.

It is actually quite easy and follows on from three facts:

· the strain diagram is straight,

· since the stress strain curve for steel at serviceability is straight, then the stress versus height plot is also straight (or we will fail the serviceability check), and

· there is no external axial force, so the total force in the section is zero.

Are we detecting a common thread here by any chance?

Let us start from an hypothesis that the stress at the centroid actually is zero. If this does not conflict with any of the rules then we can say that the hypothesis is correct.

With a straight strain line, and zero strain at the centroid, the strain at a level y above the centroid is proportional to y, and equal to k.y. The stress σ is therefore E.k.y. Please remember that signs are important and that y is negative below the centroid and the stress is therefore negative. The small amount of force δF on a small area δA is the product of stress x area so

If we add up all the little bits of force then the total force

Dividing both sides by E . k (which are non-zero constants) we get:

Since the total applied force F = 0 then F / (E . k) = 0 and

So what? Well if you think about it, the bit on the left is called the First Moment of Area and the only place about which the First Moment of Area is equal to zero is the centroid. If you have problems getting your head round that one, then use an analogy and change to the centre of gravity theory and you only get all of the products of weight times distance equal to zero at the balance point, or centre of gravity.

Hence, to have a zero total force the stress must be zero at the centroid, is proved.

That is not a circular argument, honestly, it is putting forward an hypothesis and checking to see if all the known criteria are met. Since they are, the hypothesis is proved to be true.

The next, and actually simpler, stage is to calculate the moments that arise from the calculation above.

If we now sum all of the little bits of (force x lever arm from the centroid) then

Those of you who are still (miraculously) awake, might have noticed that the last integral is the Second Moment of Area aka I, so the above can be replaced by

But from above:

Substituting into the moment equation above:

Which is the fundamental equation that we all use to get stress in steel at serviceability.

Ta Daaa.

Fundamental: be warned, this section is intended for the basic situation at relatively low levels of stress. If you are working with long whippy members then there may be some non-linear effects taking place, although these types of members would be more of a problem at ULS: here we are ignoring the instability effects and will deal with them in another section on non-linear behaviour.

At serviceability we are working under a predominantly linear part of the stress strain curve and, as stated before, we therefore cheat a bit and assume that the curve is actually a straight line. This is the very definition of a linear system and makes combined bending and axial very simple for steel.

The next bit is so basic that it is hard to know how to explain it. Try proving to someone that that a strawberry is red and you will find the same problem, but then I did say that I would try to make you take nothing on trust.

An axial force must, by definition, be applied down the centroid or there would be an associated moment. If we divide the axial force by the area, we get the axial stress and it has the same effect over the entire area. This means that the two extreme fibres of a section will be subject to an additional stress, but since the stress strain curve is a straight line then the additional strains on both will be the same. Since the additional strains are the same then the difference in the strains is the same as it was without the axial force and the curvature etc will remain the same. Also, if you work out the stresses separately for axial and bending and then add them together, taking moments about the centroid will cause the axial stresses to have no effect, showing that they do not interact.

I think that that demonstrates that the two effects can be investigated separately and added together, but I would love to hear an improved version other than “It is trivial”.

Now try proving 2 + 2 = 4. You can’t, it is just a convention since when you put two beans next to another two beans you are just recognising that there are four.

Structural steel at ultimate under pure bending

This is one of my favourites and causes the greatest discussion with my grads. “But it does not follow the stress strain curve for steel and your method is £*!!*(%$”. And that is when I explain that the stress strain curve usually shown for steel is just a little bit misleading.

It is difficult to pin down exactly what the yield stress for steel is because it does not actually give a convenient break in the graph, but let us consider the idealised curve (the thick line) in Figure 6. For the imaginary steel shown (it is only a diagram for a discussion after all) the yield is around 400 MPa (so much easier than typing in N/mm2 every time although you do have to teach Word to ignore the two capitals). With a Young’s modulus of 200,000 (are you starting to see how cunning/lazy I am yet ?) the strain at yield is 0.002, or 0.2%, since the steel is assumed to behave absolutely linearly. If I apply my scale rule to my computer screen (not a good habit but it gives me a rough idea) the end of the graph in Figure 6 is at approximately 0.7%. But would it surprise you to know that ultimate steel strains (when the steel ruptures) are more likely to be 15 to 20%, or 20 to 30 times as much as implied on the typical stress strain curve.

Figure 11 - stress strain curve for steel to scale (for once)

|

This makes the calculation of the plastic neutral axis very simple. If the stress is either +yield or –yield then making the forces add up to zero just requires equal areas above and below the neutral axis.

Hint: steel sections are generally very efficient in their design (assuming that they have been designed by an engineer rather than an architect). The classic I section (I knew that Courier font would come in useful some time) has a lot of area at the two extremes in the flanges, and another area forming the web. If the section is fairly balanced, with a centroid somewhere near the middle, then at serviceability, both flanges will be at or near yield and will therefore contribute a high component of moment. At ultimate, they will be exactly at yield, and will contribute a fraction more moment due to the entire flange plate being yielded rather than just the tips. The contribution from the webs will be σy.b.d2/6 at SLS, increasing to σy.b.d2/4 at ULS. Although the increase in the web moment is useful, it may only increase the total moment by around 10% since it is the flanges that make the greatest contribution. But for even this small increase to be achievable, the section must be able to go fully plastic and …

I got here much interesting stuff. The post is great! Thanks for sharing it! Structural engineer Bradford

ReplyDelete